Plastic

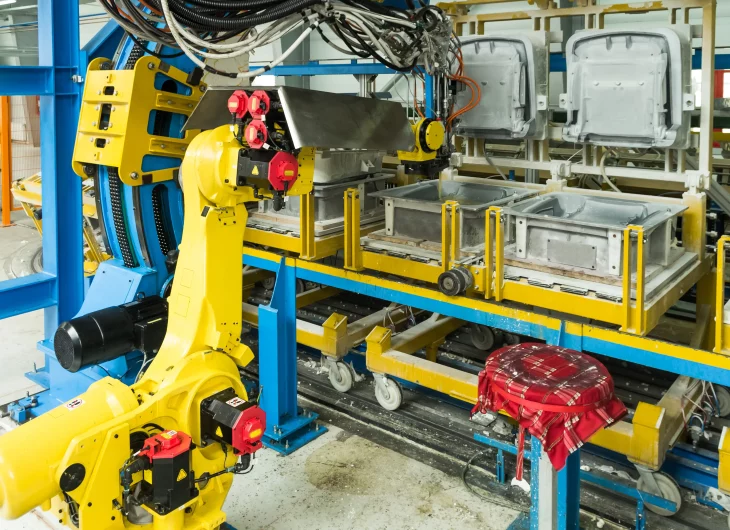

The main uses of robots and robot islands in the plastics and rubber sector are as follows:

Moulding and Handling of Plastic Components such as Injection Moulding

Robot islands and robots are normally used to remove moulded parts from injection presses and place them on conveyor belts or other processing equipment. This process increases production speed and minimizes damage to components. Robots are also used to move plastic components between different stages of the production process, such as between molding, cooling, and assembly. This automation reduces cycle times and improves accuracy.

Inspection of the Quality and Integrity of the Parts

Robotic islands can be equipped with sensors and measuring instruments to check the dimensions of plastic parts, ensuring that they meet specified tolerances, to carry out a visual inspection for surface defects such as air bubbles, deformations or imperfections in the finish, ensuring a high quality final product or for leak testing in the case of components such as tanks or containers, to ensure that there are no leaks.

Assembly of plastic and rubber parts

Robotic islands and robots are used for bonding and welding (such as ultrasonic welding) to join plastic parts, ensuring precision and consistency in the process. In the case of automatic assembly, robots are used to combine different plastic components into a finished product, such as car parts, household appliances or toys. This includes inserting, screwing and mounting various elements.

Packaging and palletising of finished products

Robotic islands can automate the entire packaging process, including product handling, container placement and sealing. This is particularly useful for consumer items such as plastic bottles, toys or electronic components. Once packaged, products can be automatically placed on pallets by robots following optimized layouts to maximize space use and ensure stability during transport.

Surface Treatments and automatic painting

Specialist robots apply paint or other coatings to plastic parts to enhance the aesthetic appearance or add functionality such as UV resistance or electrical conductivity. After moulding, some components may require special finishing, robots can perform polishing, sanding or other surface finishing operations to achieve the desired quality.

Materials Management and Recycling

Before the moulding process, robots are used to handle and transport plastic granules to processing machines, and in the internal recycling phase robots can be used to sort and handle plastic waste and recyclable materials within the plant, reducing waste and improving overall efficiency.

Investing in robotic islands in the plastics sector allows companies to optimize production processes, improve product quality and reduce operating costs, making them a strategic asset to maintain competitiveness in the global market.